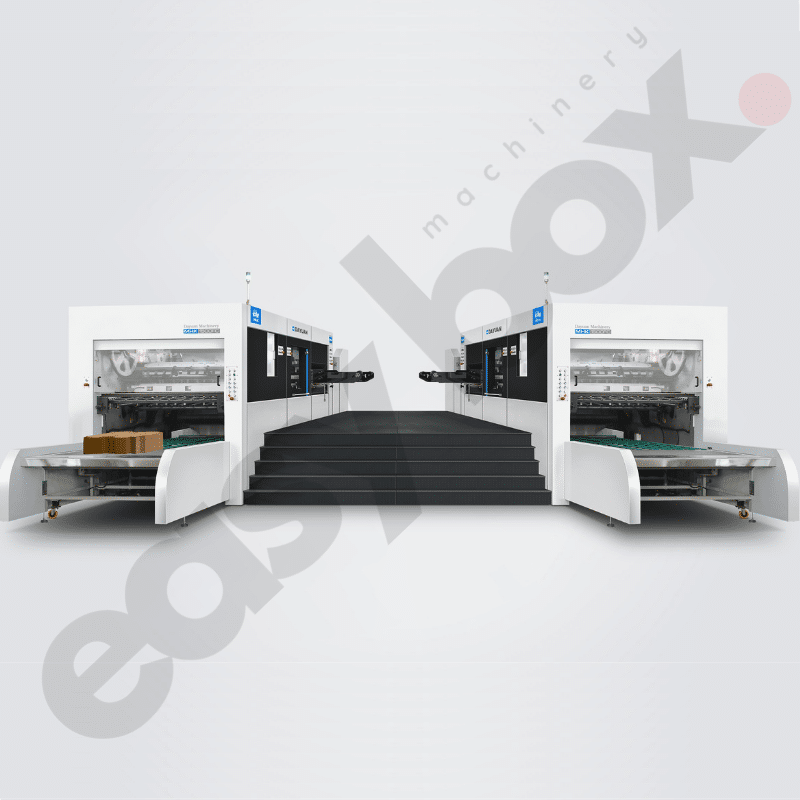

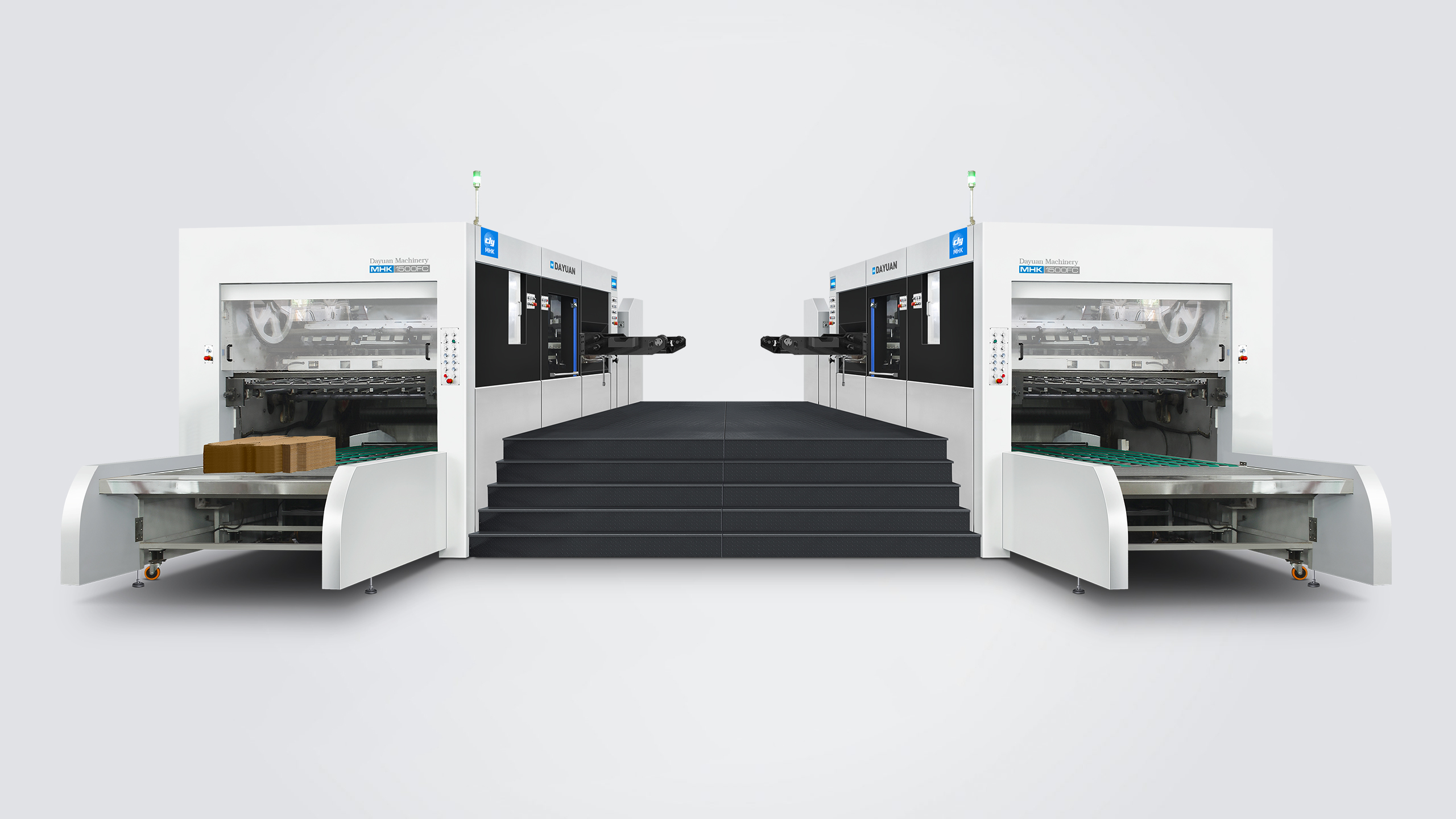

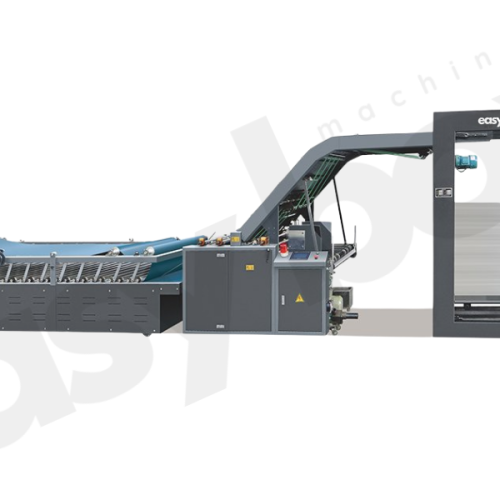

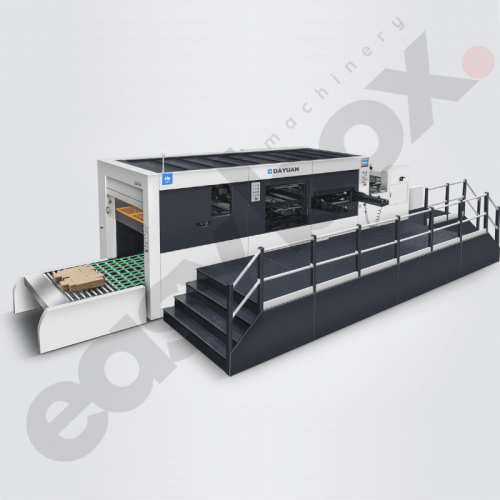

MHK 1300FC/1500FC Mirror Machines Dual Diecutter Working Station(Lead Edge Feeder)

Did you like this product? Add to favorites now and follow the product.

(+90) 212 612 93 06 Canlı Yayına Başla

Description

Introduction to the MHK 1300FC/1500FC Mirror Machines Dual Diecutter Working Station (Lead Edge Feeder)

The MHK 1300FC/1500FC Mirror Machines Dual Diecutter Working Station with Lead Edge Feeder is an advanced solution designed to enhance efficiency and precision in the packaging and printing industries. This innovative machine combines dual die cutting stations with a lead edge feeder, ensuring superior performance, high productivity, and seamless integration in modern manufacturing environments.

Key Features

Dual Diecutter Integration

The MHK 1300FC/1500FC features dual die cutting stations that operate simultaneously, significantly increasing production speed and throughput. This dual integration allows for efficient handling of high-volume production demands, reducing overall production time and costs.

Lead Edge Feeder System

The integrated lead edge feeder system ensures accurate and consistent material feeding, which is crucial for maintaining high-speed operations and reducing the likelihood of misfeeds. This system enhances the overall reliability and efficiency of the production process.

High Precision and Accuracy

These machines deliver millimeter-perfect die cutting, making them ideal for applications requiring detailed and exact specifications. The high precision minimizes material waste and ensures superior product quality, which is essential for maintaining high production standards.

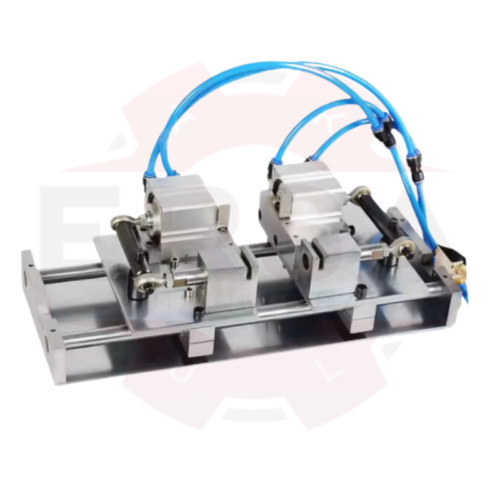

Integrated Stripping Function

The MHK 1300FC/1500FC includes an integrated stripping function that automatically removes waste material from the finished product. This feature ensures clean and precise edges, reduces manual labor, and speeds up the production process, leading to significant labor cost savings.

Benefits

- Enhanced Efficiency: The combination of dual die cutting stations, high-speed operations, and an integrated stripping function streamlines the workflow, reducing downtime and labor costs.

- User-Friendly Interface: An intuitive touch-screen display provides easy setup and real-time monitoring, minimizing the learning curve for operators and ensuring smooth operation.

- Safety Features: Equipped with emergency stop buttons and protective guards, the machine ensures a safe working environment, adhering to the highest industry standards.

Applications

The MHK 1300FC/1500FC is perfect for a variety of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and efficiency make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

Conclusion

The MHK 1300FC/1500FC Mirror Machines Dual Diecutter Working Station with Lead Edge Feeder sets a new industry standard with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, these machines help businesses increase productivity while maintaining high quality and safety standards.

Area Saving

| 2 Regular Machines Floor Space | Mirror Machines Floor Space | Total Space Saved | |

| With Chase Loader | 197.3m² | 148.5m² | 48.8m² |

| Without Chase Loade | 172.2m² | 142.8m² | 27.4m² |

Because the same foot pedal is shared, the intermediate channel (at least 2×10 meters) when the two machines are placed separately, can save 2×10=20m2 of plant occupation area.

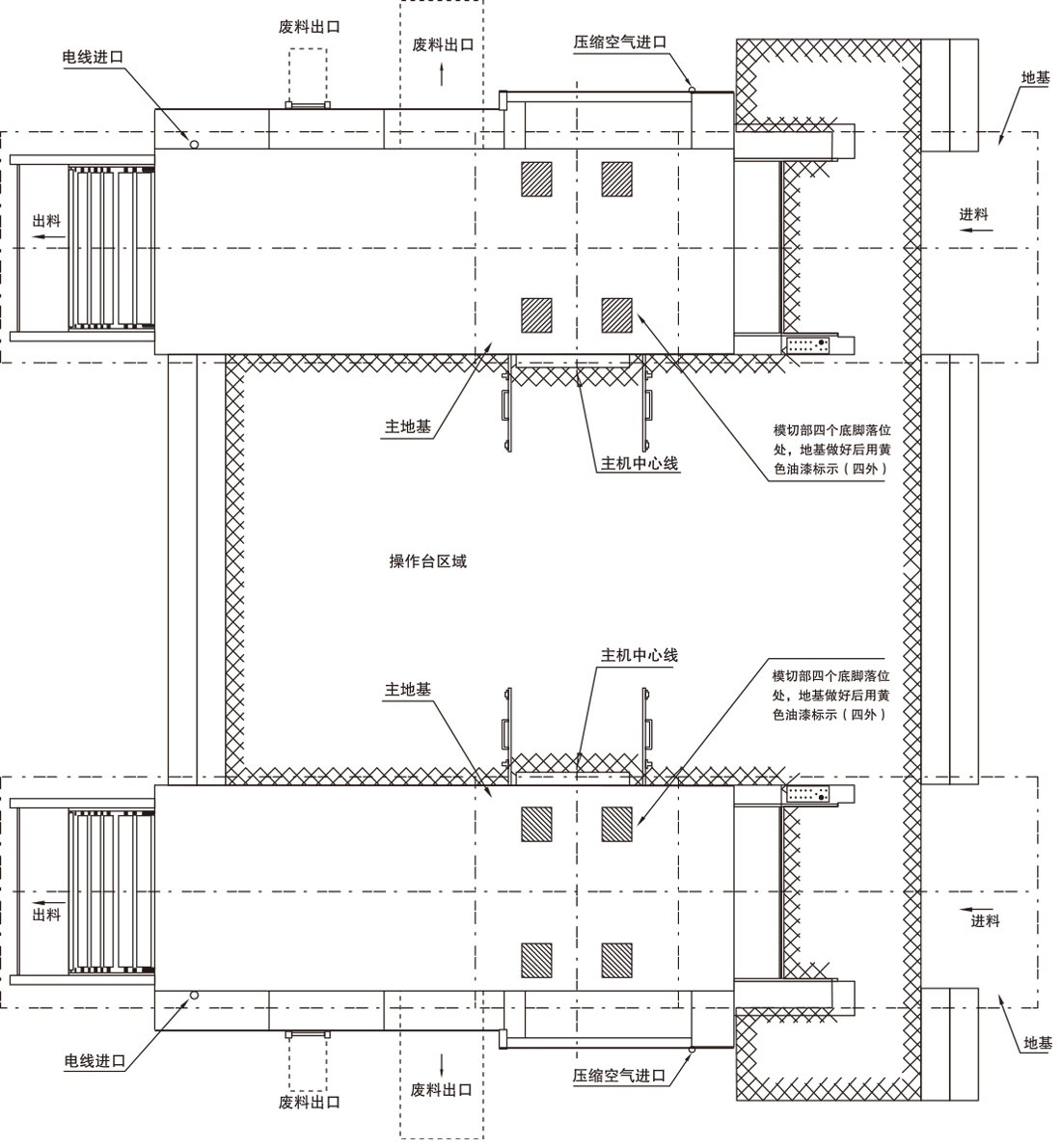

Drawing

Reviews

There are no reviews yet.